AN ITALIAN STORY WITH A UNIQUE FLAVOUR.

Find out the history of Aceto Varvello, from its establishment to the attention paid by the company to the environmental sustainability thanks to the use of the renewal energies.

-

From the 1920s to the first post-war period

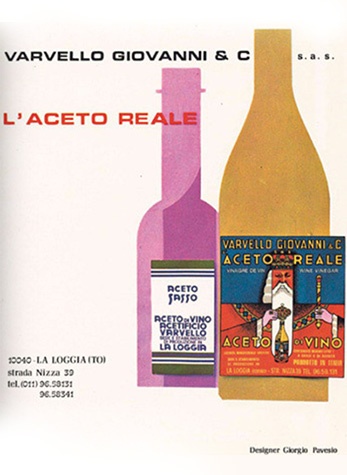

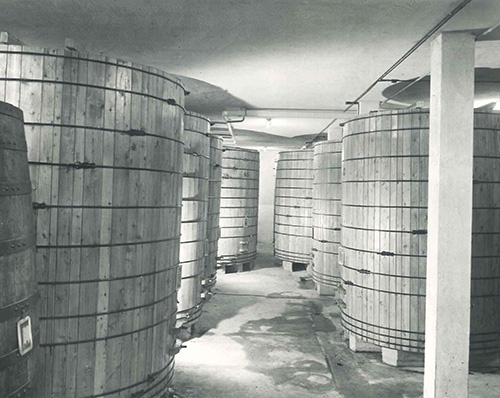

Our company was established in Turin in 1921 by the entrepreneurial spirit of the Commander Giovanni Varvello and by his intuition which has proven us right over the time. Indeed, he understood before anybody else the need to use quality wines to produce an equally noble vinegar on an industrial scale. It was then that in the warehouses underlying his house in Via Nizza, 135 (135, Nizza Street), Giovanni Varvello founded the “Stabilimento Italiano l’Aceto” (“Italian Plant the Vinegar”). Over the years his business had made giant steps thus becoming one of the major vinegar producers in Italy. Then the War broke out and everything became complicated. However, the production resumed shortly and hence the turnover.

During the Second World War, bombs destroyed the Turin plant. Almost ruined, Varvello moved to Portacomaro, a village in the Asti area. Not even the Great War could intimidate the family company that took up the production of vinegar in the premises of the prestigious Palazzo Riscossa. The choice of Asti proved to be a winner, thanks to its strategic position: indeed, the railway guaranteed the arrival of wine in barrels and the subsequent delivery of the vinegar.

The entire production was entrusted exclusively to the wise hands of women, since the men were called to fight in the war. -

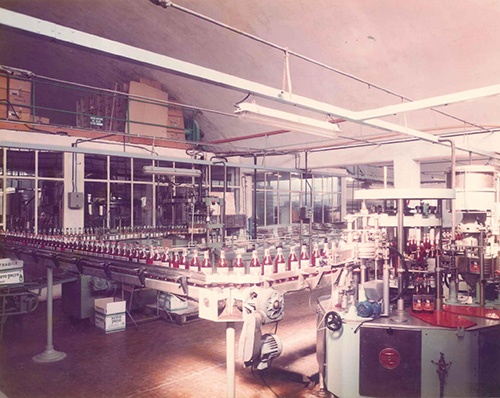

The 1960s: the age of development

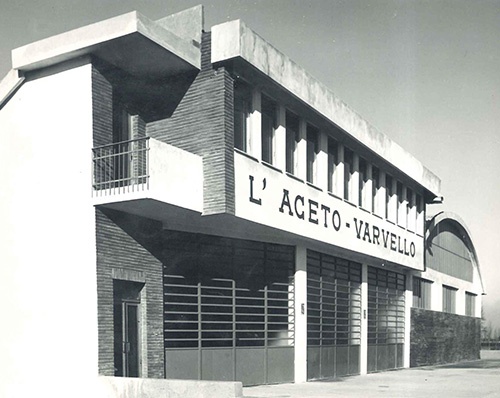

The years of the economic boom saw the Varvello company to grow continuously and in 1961 the founder’s sons, Gianfranco and Piergiorgio, decided to transfer the business to its current location in La Loggia, Via Nizza, 39 (39, Nizza Street). Varvello was increasingly asserted as a leading company in its sector. Numerous collaborations then started with the major brands in the food sector, with Saclà being in the lead.

-

The turning point

But the real turning point came in the early 1970s, when a new type of table vinegar was launched, RISERVA, aged in oak barrels and made from superior quality wines. In a short time this new intuition of Varvello became a point of reference for the whole classification and restored the "nobility" to the vinegar that such a condiment deserves.

-

The period of great collaborations

In the late 1970s and early 1980s, collaborations began with other national industrial groups such as La Rinascente, Garosci and Vegè. However, even foreign groups, mostly English and German such as Khune and British Vinegar, showed interest in an excellent quality product and started partnerships that would determine Varvello's success also in the European market.

-

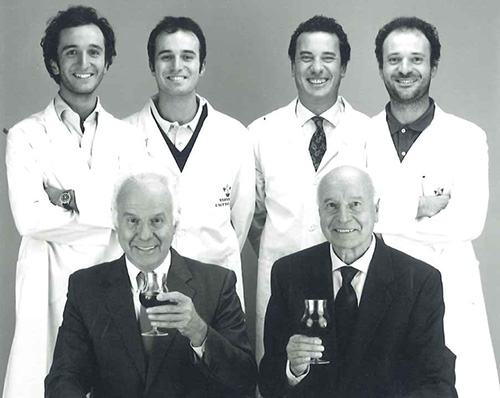

The third generation

Towards the end of the 1980s and the beginning of the 1990s, the third Varvello generation, with Marco and Roberto, is focused on a new market trend: that of private labels of large-scale retailers. Varvello is therefore working alongside with the leading Italian and foreign groups in the distribution chain such as GS, Diperdì, Carrefour and Auchan, just to mention the most important and well-known brands of Italian large-scale distribution.

-

The challenges of the new millennium

The advent of the third millennium is full of challenges and new opportunities.

BIO vinegars are born and, in a short time, we become a reference point for an industry that intends to grow with respect to the environment.

Today the axis of our production focuses on the BIO product. Consumers are starting to pay attention not only to the taste and quality product but they are also concerned to a wise organic choice. Varvello responds to this new market by offering a wide range of organic products that meets the favour of the public to start with and is increasingly directed towards a healthy and balanced diet.

Alongside to the interest in organic farming, we are witnessing a great technological transformation.

These are the years of the new industrial "revolution" in which Varvello 4.0 is formed. The factories are increasingly becoming digital and are now aiming to a fully automated industrial production.

The Varvello company is ready for such a change. We take this new challenge.

The new "Industrial Revolution" does not neglect quality: in a few months the Apple Vinegar production will start that is made with apple cider from local cooperatives, thus paying great attention to quality and privileged selection. This choice will allow Varvello to be able to interact directly with the producers, to directly follow the entire production process from the fruit that is still on the tree to the table. -

Diversification

In 2015 the Acetaia of Bastiglia first appears next to the historic Piedmontese factory of La Loggia, in the heart of the typical Modena area of the production of Balsamic Vinegar of Modena PGI. Thus a new warehouse and a production area is dedicated to the glaze with balsamic vinegar of Modena P.G.I. Thanks to new technologies, the market is preparing to taste the new fruity vinegars that will be used not only as a seasoning vinegar, but also as an ingredient for toning drinks based on apple, pear, kiwi, pomegranate, etc ...

In addition to this, the successful collaboration between the “Azienda Agricola per l’Aceto Balsamico Tradizionale di Modena DOP” (Rural Business for the Traditional Balsamic Vinegar of Modena PDO) and a historic Bastiglia family led to a wider range of products and, at the same time, to a reduction in the supply chain. From here high-quality vinegars and condiments are born in addition to the now famous vinegars aged 12 and 25 years.

Piedmont is well-known for the great variety of its apples and the numerous events organized on the regional territory witness the dedication of the local producers to apple growing. This plays to the advantage of Varvello that is not embarrassed to choose the most resistant, tasty and aromatic apples. The possibility to select the best products directly guarantees to our company the complete and clear vision of the entire production cycle, from the fruit to the table.

-

The years of environmental awareness

The third millennium marks also for Varvello the beginning of new company policies regarding the environment and the development of projects on the production of energy derived from renewable sources. Today are using more than 60% of the energy required for the production using solar panels.

Glass and recycled plastic are being used for packaging. Thanks to a technologically advanced system on the PET bottling line, it is possible to obtain directly different types of bottles and containers, in order to optimize resources and consumption. Furthermore, the residues from vinegar processing are being used as natural fertilizers.

At Varvello we understand the value of our environment and we do everything we can to respect it. -

Green Economy Sustainability

To us sustainable development is not an abstract concept, but a commitment that involves the entire company and the entire production cycle.

The sustainability path began with the 14001 environmental certification of the La Loggia production complex and has been consolidated over the years.

In 2014 Varvello also received the ISO 50001 certification that has recently extended to the new site in Bastiglia.

There are other technical improvements that have reinforced the “green” heart of the company, such as the replacement of boilers and compressors, the installation of LED lighting, the optimization of heat recovery and the installation of an evaporative tower. All of which have allowed savings to be made in energy and water and consequently to reduce emissions.

Moreover, Varvello uses renewable sources thanks to which a self-consumption of about 300,000 kWh is guaranteed. One of the Company's main objectives is the exploration of new improvement interventions to save energy and to reduce GHG emissions according to ISO 14064 certification.

Over the years the following results have been achieved:- Electricity savings;

- Thermal energy savings;

- Water Saving;

- Emissions prevention.